When there are new techniques and ideas, there are myths and facts. You must have heard about mandrel bending, and if not, then we are here to introduce you to it. It does have some benefits, but it does has many myths that follow. Take a look at this guide and you will know.

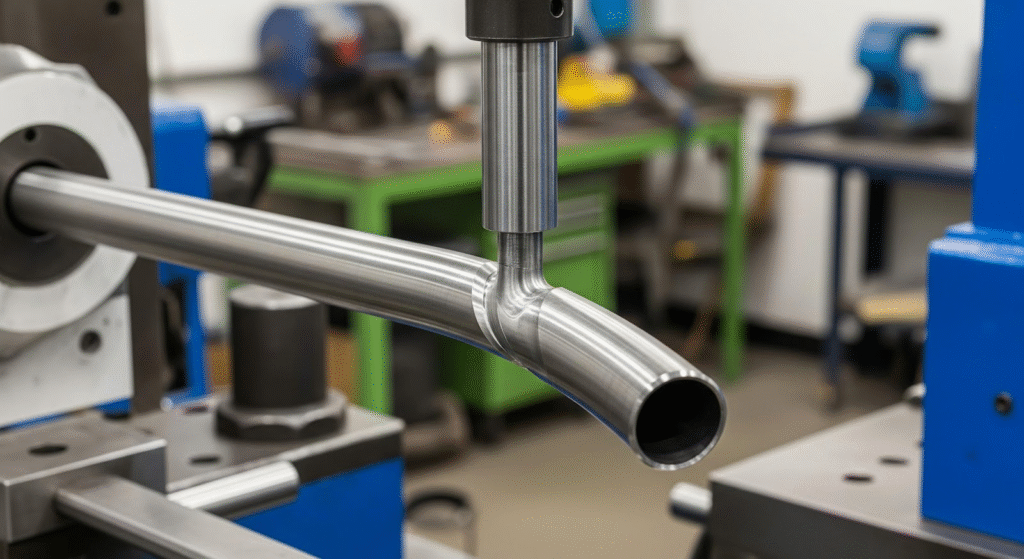

First things first, what is mandrel bending? It is a tube and pipe bending technique that uses a mandrel, a solid rod or a series of balls, inserted into the tube’s interior to prevent deformation. If you want to achieve precise, high-quality bends, especially with thin-walled tubing or when tight radius bends are required, then this is the one you should go for.

There can be some misconceptions or myths about mandrel bending which we are going to clear up for all of you so that you can move ahead with a clear mind.

Table of Contents

Mandrel Bending: What is It?

As discussed above, mandrel bending is a tube and pipe bending technique that uses a mandrel inserted into the tube’s interior to prevent deformation. The mandrel acts as internal support, preventing the tube from collapsing or kinking as it’s bent.

Mandrel bending has several benefits, including cost-effectiveness, precision in bending and reduced deformation. It can benefit various industries, including automotive, aerospace, shipbuilding and construction.

A mandrel tool can provide internal support to the tube, preventing it from wrinkling during bending. It helps maintain the tube’s shape and provides you with precision and accuracy. While there can be some traditional methods, this method can be beneficial if precision and high-quality results are priorities.

Mandrel Bending: Separating Myths and Facts

There can be many myths and facts about mandrel bending, and we have separated both for better understanding and decision making for your business. Take a look at the given myths and facts:

Myth: Bending is Weaker than Welding.

Fact:

Bending and welding are common metal fabrication techniques. The strength of each method depends on various factors, including material type, dimensions, and the specific application. In some cases, bending can even lead to work hardening, potentially leading to more strength.

Bending involves deforming metal into a desired shape without cutting or joining. It can be done using various methods like press brakes, tube benders, or even manually with tools. In some cases, bending can actually increase the strength of the material due to work hardening, where the metal becomes stronger and more resistant to deformation as it’s bent.

Myth: Heat Treatment is Always Necessary after Bending Stainless Steel.

Fact:

While heat treatment can enhance material properties, it is not always required. In mandrel bending, heat treating stainless steel is not a necessity.

While heat treatment can improve properties like ductility and corrosion resistance or create hard structures, it’s not like you have to do it. In some cases, it may even introduce problems, especially if not applied correctly.

Myth: Mandrel Bends Cannot Achieve the Same Consistency as Pre-made Fittings.

Fact:

Mandrel bending, when done by professionals, can produce bends with consistent diameter, wall thickness, and strength comparable to pre-made fittings. In fact, if you want more accuracy than welding, mandrel bending can be a good option.

It involves using a solid mandrel inside the pipe or tube to support the material during the bending process, preventing deformation and maintaining a consistent diameter. It can achieve consistent wall thickness, ovality, and strength comparable to pre-made fittings when done with proper technique and equipment.

Myth: Mandrel bending is too expensive for general use.

Fact:

Mandrel bending can have higher upfront costs compared to some other bending methods, but the overall cost savings and quality benefits often outweigh these initial expenses, making it a viable option for many applications.

It minimises material deformation and scrap, leading to less wasted material compared to other methods like crush bending, where the pipe’s cross-section can be compromised. It can be faster and more efficient, reducing the time and labour required for bending, especially for complex or intricate bends.

It reduces the need for rework and improves the quality of the finished product. While it might not be the best choice for every single bending application, it is particularly cost-effective for intricate tasks and situations where maintaining the pipe’s cross-section is crucial.

Final Thoughts

Mandrel bending reduces the risk of wrinkling, flattening, or collapsing the tube during the bending process. You can ensure a smooth, consistent bend without worrying about the issues.

If you also want to adopt this for your work, then look for mandrel tube bending. It can be effective, time-saving, cost-effective and precise than some other traditional methods. It can be highly beneficial, particularly when dealing with tight radius bends and thin-walled tubing.